Precise down to the smallest Μμ

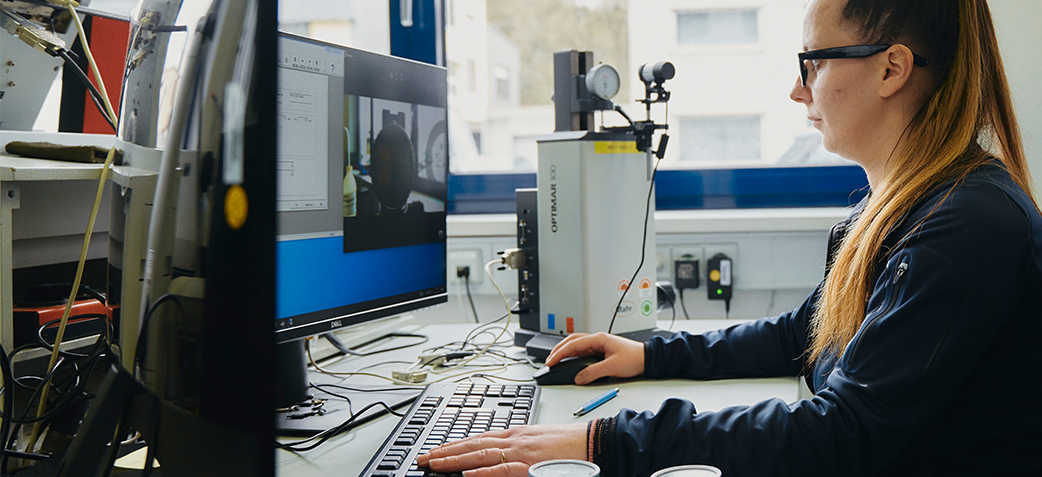

As your precision manufacturer we can apply almost any process for you. From prototype to series-ready components, we ensure that our parts and assemblies meet your requirements. The highest degree of automation and security through optimal cooperation between design and production is also guaranteed. We are certified according to all important management systems and use all major quality methods and analysis tools.

Whether ready-to-install or for further processing:

we manufacture exactly the high-quality precision part you need.

From prototype to series-ready component, we are your precision manufacturer.

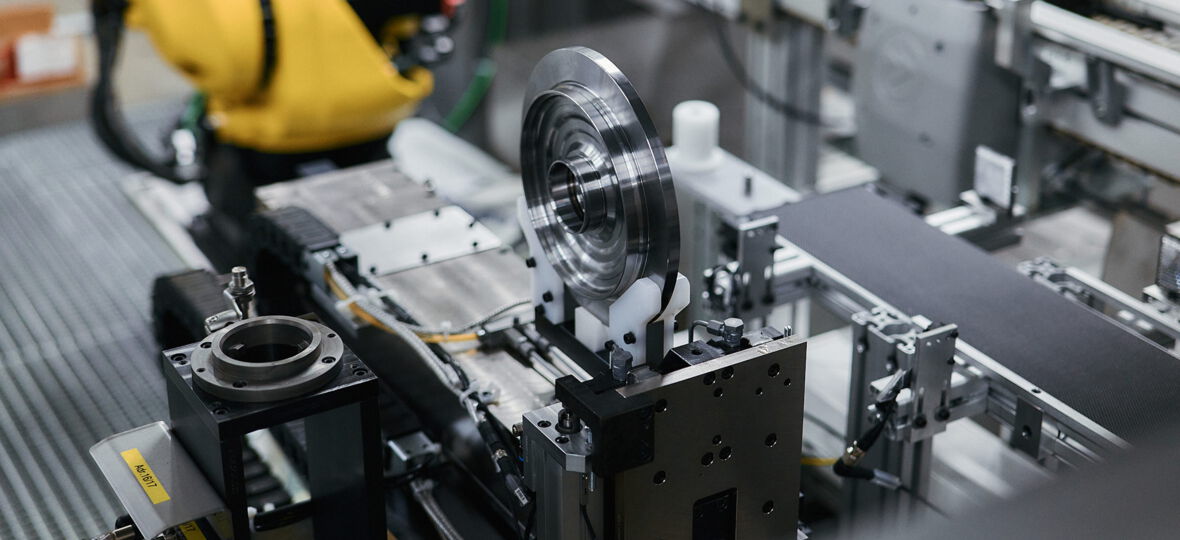

Excerpt from our production processes

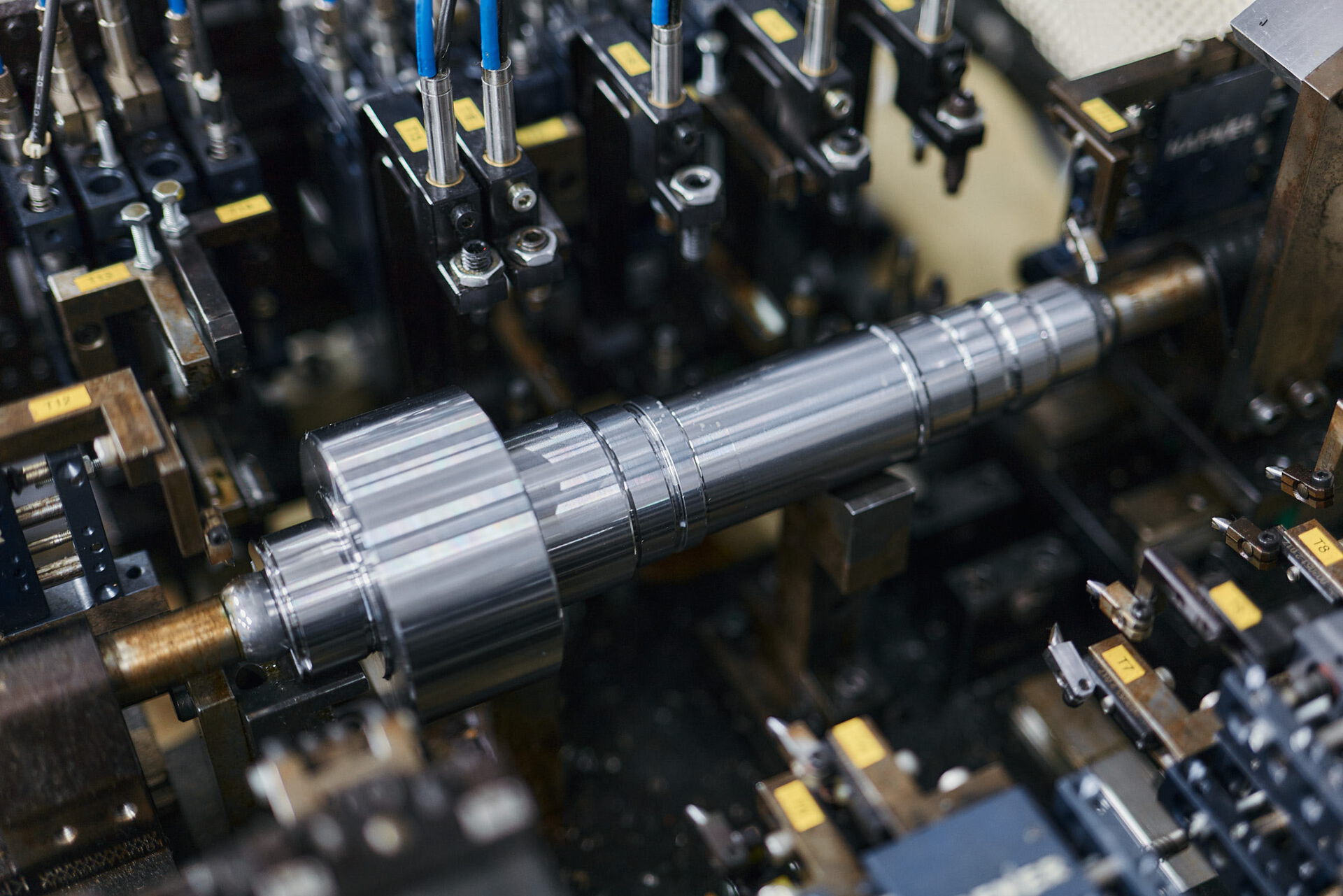

| CNC turning on single and multi-spindle machines | CNC rotary processing |

| CNC machining centers | CNC grinding: external, internal, non-circular, surface grinding |

| ECM deburring | Shot peening |

| High-pressure deburring | Honing |

| Inductive hardening | Laser welding |

| Broaching | Cleaning blasting |

| Straightening & tempering | Superfinishing: band, stone, plane finishing |

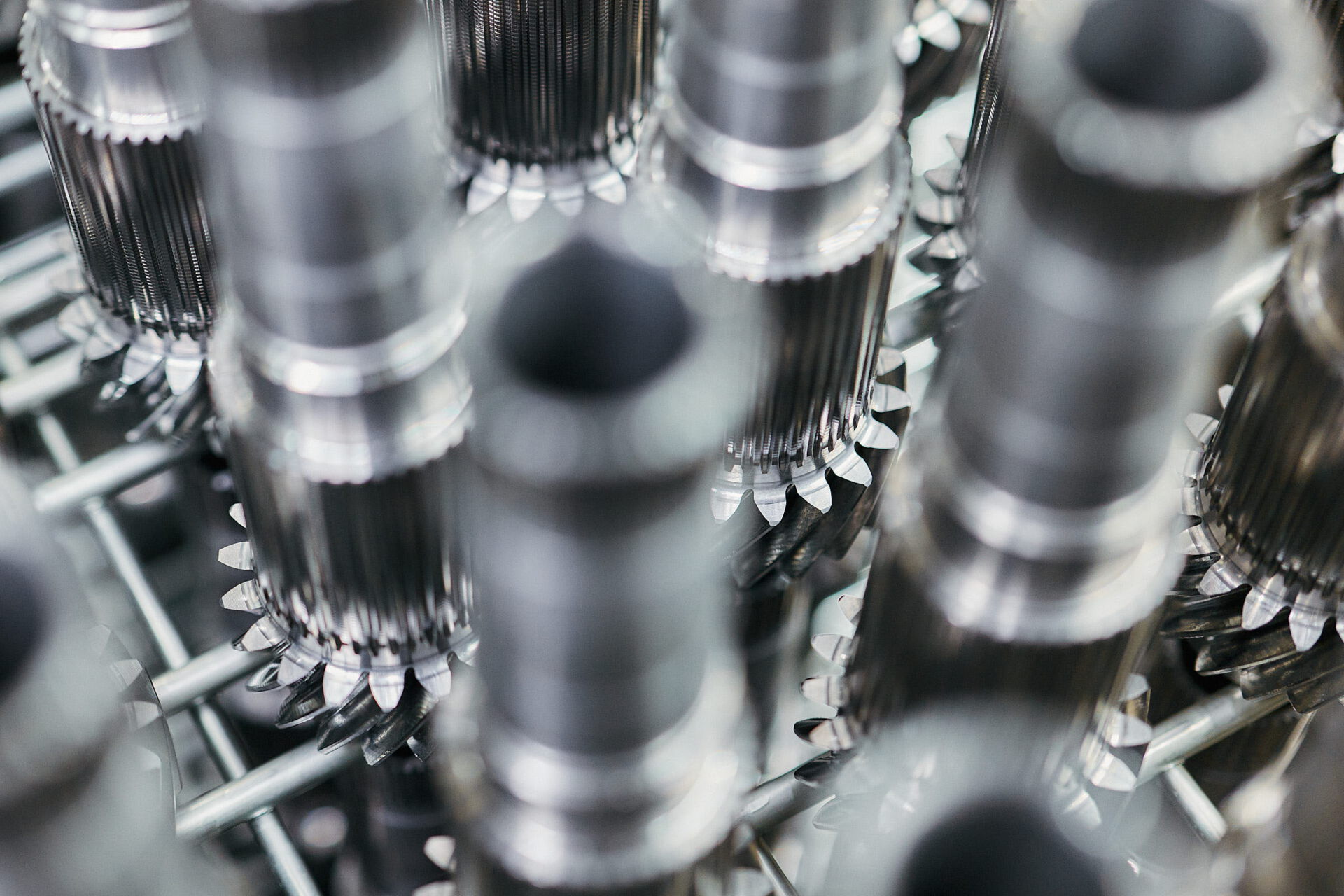

| Deep-hole drilling | Gear cutting: rolling, milling, slotting, skiving, roller burnishing |

| Gear grinding: not corrected, topologically corrected, NVH-optimized | Fully automated building of assemblies |

The highest degree of automation and security through optimal cooperation between design and production is also guaranteed.

Contact

Do you have any questions, requests or a specific order? We look forward to hearing from you.

Contact us!

Phone +49 71 93 55-0

E-Mail info@erkert.de